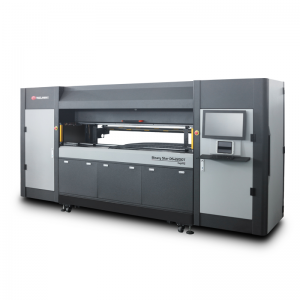

DS-3200T ON (Integrated with Heater Machine)

Features

Diverse Printheads Permutation Modes

CMYK/CMYK LC LM Support 6 colors custom solution

Machine Features

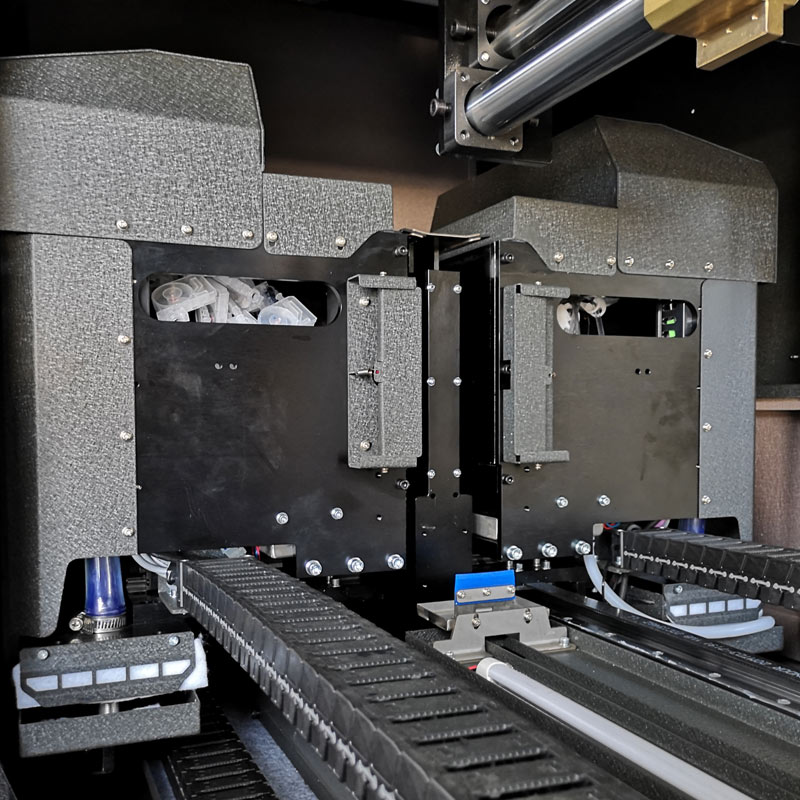

1 It's equipped with two carriages of staggered row industrial Konica printhead KM1024i 13pl.

2 The image size parameters can be adjusted freely according to the design requirements. Achieve a variety

of custom application solutions, such as same image same color, same image different color, different image

different color.

3 Two carriages asynchronously print and automatically adjust the distance between the printing media.

Support printing up to ≦2mm soft roll to roll media.

4 Dual constant temperature water-cooled variable frequency air suction platform, synchronously cools the

excess temperature on the surface of printing media to ensure the flatness of printing media.

Product Advantages

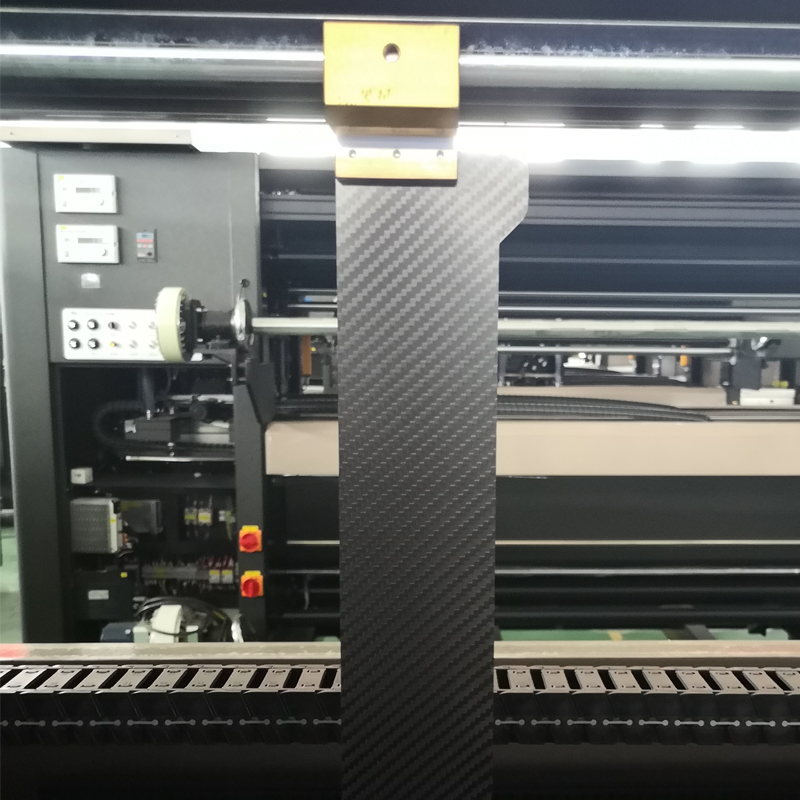

Clamp design

Some printing materials have the problem of edge rough or curling. When printing these materials, it is necessary to install the clamp device. Adapt to more materials printing.

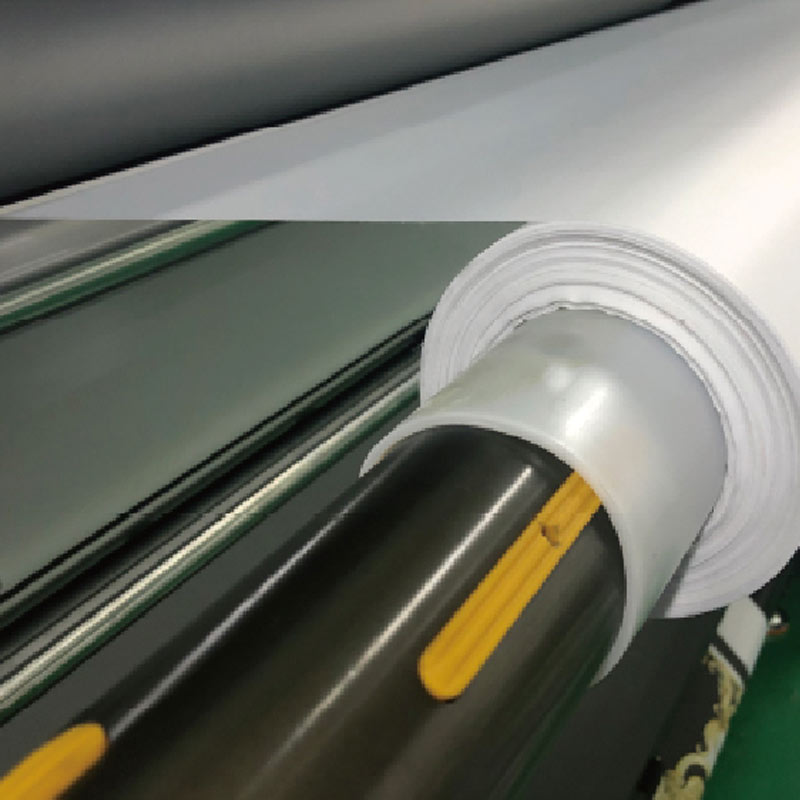

Feeding and takeup system

Use constant tension feeding and takeup system of textile equipment, magnetic powder controls feeding and takeup,110mm double rubber covered rollers feeding cloth, can be adjusted freely according to the thickness and tension of the material.

Crashproof Devices

Double directions, total 4pcs crashproof devices for 2 carriages,well protect the nozzles.

Application

Technical Parameters

| Printer Model | DS-3200T-ON | ||||

| Printhead | Kyocera KJ4B-0300/KJ4B-0600(4-8H) | ||||

|

Printing Speed |

Printing Mode | High Resolution Mode | Printing Speed | High Speed Mode | Printing Speed |

| 4pass | 635*2400 | 60㎡/h | |||

| 3pass | 635*1800 | 80㎡/h | 461*1800 | 100㎡/h | |

| 2pass | 635*1200 | 120㎡/h | 461*1200 | 150㎡/h | |

| 1pass | 635*600 | 200㎡/h | |||

| Printhead | Ricoh G6 (4-16H) | ||||

|

Printing Speed |

4pass | 635*1200 | 40㎡/h | ||

| 3pass | 635*900 | 55㎡/h | |||

| 2pass | 635*600 | 80㎡/h | |||

|

Ink |

Type | Water-based Ink | |||

| Color | M / Y / C / K / LM / LC (O, B optional,FM,FY) | ||||

| Media Max Diameter | 350mm | ||||

| Printing Width | 3200mm | ||||

| Printing Thickness | ≦3mm | ||||

| RIP Software | Maintop/PrintFactory/NeoStampa/PP | ||||

| Image Format | TIFF /JPG /EPS /PDF | ||||

| Data Transfer | TCP/IP network interface /USB | ||||

| OS Required | Windows7/10 64 bits (Flagship/Professional Version) | ||||

| Computer Required | Hard disk: SATA500/Hard disk format: NTFS/CPU: Inter i5/RAM: 8G -16G | ||||

| Drying System | Synchronous drying before and after printing, the temperature can be adjusted according to different fabrics. | ||||

| Ink Purge Control System | Automatic printhead cleaning, ink scraping and moisturizing system by patent | ||||

| Media Type | Chemical fiber, Banner cloth, light box cloth etc | ||||

| Maximum Power | 25KW (Pre-drying power 5.6KW, heater machine power 16.8KW) | ||||

| Operation Environment | Humidity: 40%-70% Temperature: 20-30℃ | ||||

| Power Supply | AC380V±10% 50HZ | ||||

| N.W | 3600kg | ||||

| Printer Size | L*W*H: 6135*2135*2217mm | ||||

| Package Size | L*W*H: 6300*2000*2500mm | ||||